Fondata nel 1926, Novacart è la più grande azienda a ciclo completo di prodotti in carta e cartoncino per uso dolciario e alimentare, con una produzione di svariati milioni di pezzi e sedi in tutto il mondo. Fin dalle origini, ci siamo distinti per l'attenzione alle esigenze del mercato e per l'elevata qualità dei prodotti.

Soluzioni e servizi

Novacart risponde alle esigenze di ogni cliente offrendo soluzioni e servizi mirati per l’industria alimentare, per i professionisti del settore dolciario e per la grande distribuzione.

In primo piano

Tutti i prodottiI numeri del nostro gruppo

- Numero di dipendenti 0

- Paesi nel mondo 0

- Sedi produttive 0

- Unità commerciali e logistiche 0

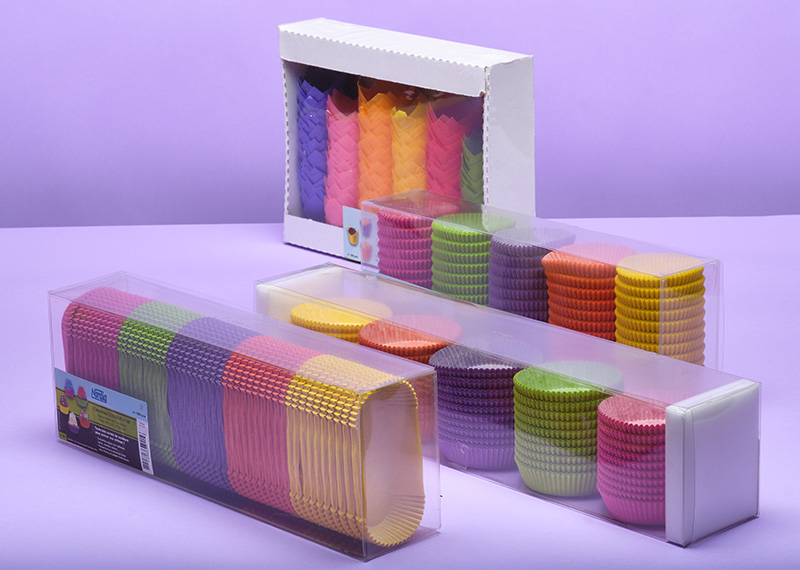

- Forme di cottura 181.108.082

- Pirottini da cottura 2.112.927.624

- Altri prodotti 301.846.803

Una presenza globale

Innovazione

La spinta all'innovazione, all'esplorazione di nuovi mercati e all'introduzione di novità nel settore è da sempre uno stimolo al nostro lavoro.

Certificazioni

Novacart ha ottenuto le più importanti certificazioni per qualità, sicurezza e trasparenza.

Novacart fa parte di Sedex, organizzazione internazionale a sostegno di pratiche aziendali etiche e sostenibili nella gestione dei processi produttivi.

Sostenibilità Ambientale

-

Stiamo lavorando verso un futuro a

ZERO EMISSIONI

- 1,413 MWp potenza Impianto

- 0 Ton Co2 evitata/anno

- 0 TEP evitati

- 0 Alberi equivalenti salvati

Nuovo impianto fotovoltaico - 2.480 Pannelli fotovoltaici - 1.490.000 KW/h prodotto in un anno

Fiere

Scopri le prossime fiereCrediamo nell’importanza di momenti di confronto con i clienti. Scopri le prossime fiere in cui saranno presenti le aziende del Gruppo Novacart.

-

Gran Via, Barcellona 07/05/2024 -

10/05/2024 Hispack Padiglione 2, Livello 0, Hall E, Stand 160Hispack - Gran Via, Barcellona

07/05/2024 - 10/05/2024

Padiglione 2, Livello 0, Hall E, Stand 160 -

RIYADH - KSA 30/04/2024 -

02/05/2024 SaudiFood Manufacturing E1-30SaudiFood Manufacturing - RIYADH - KSA

30/04/2024 - 02/05/2024

E1-30